Exploring the Advantages of Utilizing Bulk Containers in Modern Supply Chains

Using bulk containers in modern supply chains provides a range of benefits that are worthy of cautious factor to consider. These containers can result in significant cost financial savings while enhancing logistical effectiveness. They additionally play an important role in minimizing product packaging waste and enhancing storage space services. As sectors increasingly prioritize sustainability, the prospective influence of bulk containers becomes a lot more appropriate. What particular benefits can be understood by adopting this strategy?

Price Financial Savings Through Bulk Handling

Mass handling supplies significant price savings for businesses within modern-day supply chains. By using bulk containers, companies can reduce packaging costs significantly, as less materials are needed for transportation and storage. This reduction in product packaging not just reduces costs yet also reduces waste, straightening with sustainability goals. Additionally, bulk handling allows much more efficient transport, as larger quantities can be delivered in fewer journeys, leading to lowered products costs.

Labor costs additionally see a decrease; bulk materials generally need much less hands-on handling, enabling staff to concentrate on various other value-added jobs. The structured storage space of bulk containers maximizes storehouse space, leading to prospective savings in rental or operational costs - refurbished bulk containers. In general, carrying out mass handling approaches can significantly enhance an organization's profits, making it an eye-catching alternative for companies looking to enhance their price efficiency in an open market

Enhanced Effectiveness in Logistics

While typical supply chain techniques commonly include fragmented processes, the combination of mass containers significantly improves logistics effectiveness. These containers promote the structured motion of goods, reducing dealing with times and minimizing the demand for numerous transfers. By consolidating products into less shipments, companies can enhance transport routes and decrease total products costs.

The enhanced exposure provided by bulk logistics enables real-time monitoring of shipments, allowing supply chain managers to react swiftly to any type of interruptions. On the whole, the fostering of bulk containers transforms logistics procedures, cultivating a much more responsive and agile supply chain that meets the needs of contemporary business.

Reduction of Product Packaging Waste

As companies look for to improve sustainability in their procedures, using mass containers plays an essential function in lowering product packaging waste. Conventional packaging methods usually involve numerous layers, resulting in significant waste, both in products and disposal. By making use of mass containers, services can notably minimize the amount of packaging called for, as these containers are made to be reused and reused. This shift not just lowers the volume of single-use product packaging sent to land fills yet also decreases the carbon impact related to manufacturing and carrying packaging materials. Additionally, mass containers help with more efficient loading processes, allowing for a greater amount of products to be moved at when, thereby reducing the demand for excessive packaging. Inevitably, adopting mass containers leads to a much more lasting supply chain, aligning functional exercise with ecological responsibility while likewise potentially minimizing costs connected with product packaging waste management.

Improved Storage Space Solutions

Efficient storage space options are crucial for maximizing supply chain performance, specifically when mass containers are utilized. These containers make best use of room utilization, permitting greater density storage. Their uniform measurements make it possible for stacking, which minimizes the impact required in storage facilities and warehouse. This organization not just boosts accessibility however likewise enhances inventory monitoring.

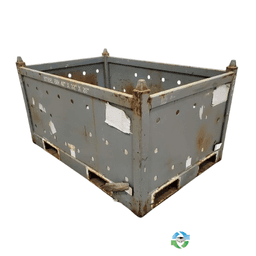

Additionally, bulk containers can be made to suit numerous materials, from fluids to solids, therefore using versatility in storage space alternatives. Their durable construction guarantees resilience, decreasing the risk of damage throughout handling and transportation. Companies can experience fewer interruptions and reduced replacement expenses.

Moreover, the standardization of mass containers facilitates much easier assimilation right into automated storage and access systems, additionally boosting functional efficiency. To conclude, the fostering of mass containers brings about improved storage options that sustain structured procedures and add positively to total supply chain effectiveness.

Promoting Sustainability in Supply Chains

Promoting sustainability in supply chains has actually become an essential focus for businesses looking for to minimize their environmental influence. The fostering of mass containers offers as a pivotal strategy for improving sustainability initiatives. These containers, created for efficient storage space and transportation, significantly decrease product Recommended Site packaging waste contrasted to standard packaging methods. By making use of durable products, bulk containers can be reused numerous times, additionally reducing the demand for single-use packaging.

In addition, mass containers optimize logistics by making best use of area use throughout transportation, thereby lowering carbon discharges associated with delivery. Services can also streamline their supply chain procedures, which adds to lowering energy intake. Additionally, business that prioritize sustainability frequently enhance their brand reputation, appealing to eco aware consumers. Overall, integrating bulk containers into supply chains not only promotes environmental duty yet also fosters functional efficiency, demonstrating a complete technique to sustainable business methods.

Frequently Asked Questions

What Sorts of Products Are Finest Matched for Mass Containers?

Products ideal matched for bulk containers consist of grains, chemicals, fluids, and huge components. These products take advantage of effective storage space, transport, and reduced packaging waste, eventually enhancing operational performance and cost-effectiveness within supply chain processes.

How Do Mass Containers Influence Inventory Management Practices?

Mass containers improve inventory monitoring by reducing taking care of times and optimizing storage area. They improve presence of supply levels, streamline tracking, and help with more accurate forecasting, eventually resulting in improved effectiveness and minimized functional costs.

Are There Particular Industries That Benefit Most From Bulk Containers?

Specific sectors, such as agriculture, chemicals, and food processing, benefit most from bulk containers. used bulk containers. These industries make use of bulk containers to enhance important site performance, decrease costs, and boost logistics, eventually enhancing their supply chain operations considerably

What Are the Security Considerations When Utilizing Bulk Containers?

Safety considerations when utilizing bulk containers include making sure architectural stability, appropriate handling methods, secure loading and dumping procedures, regular evaluations for leaks or damage, and compliance with pertinent policies to mitigate hazards during transport and storage.

How Can Business Change to Mass Container Solutions Efficiently?

Firms can efficiently shift to bulk container systems by reviewing present logistics, training staff, slowly implementing the brand-new system, assessing distributor capabilities, and continuously checking efficiency to guarantee efficiency and security throughout the procedure. (used bulk containers)

The useful source use of bulk containers in modern supply chains offers a variety of benefits that are worthy of careful factor to consider. By using bulk containers, business can lower packaging expenses significantly, as less products are required for transport and storage. While traditional supply chain approaches usually include fragmented procedures, the combination of bulk containers considerably improves logistics efficiency. By using bulk containers, companies can significantly reduce the quantity of product packaging required, as these containers are made to be reused and recycled. Efficient storage space remedies are necessary for enhancing supply chain efficiency, especially when bulk containers are utilized.